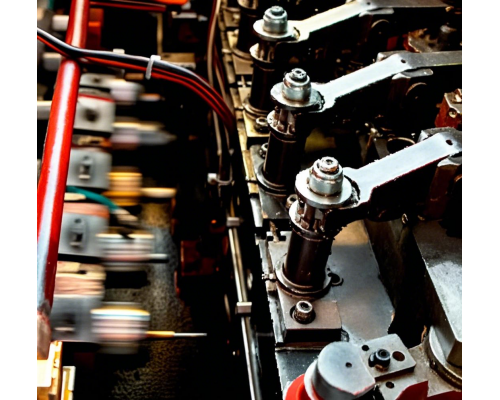

Mass Production

Company Cold Heading Processing Service Introduction

I. Service Overview

We provide customers with comprehensive cold heading processing services, covering the entire process from product design optimization, mold development and manufacturing, to cold heading production and finished product inspection. With a professional technical team and rich industry experience, whether it is standard parts or customized special-shaped parts, we can provide one-stop solutions from scheme design to product delivery according to customer needs, ensuring that each product meets the performance and quality requirements of customers.

II. Processing Capabilities

The company is equipped with multiple advanced cold heading forming equipment of different specifications and models. The maximum diameter of the processed wire can reach 20mm, and the processable materials include various metal wires such as carbon steel, alloy steel, stainless steel, copper alloy, and aluminum alloy. The equipment has high-speed and high-precision processing performance, capable of achieving hundreds of upsetting times per minute, while ensuring that the product size accuracy is controlled within ±0.05mm. In addition, we also have complete auxiliary processing equipment, which can perform subsequent surface treatment, heat treatment, and other processes on cold headed parts, providing customers with complete product solutions.

III. Core Advantages

- Efficient Production:Cold heading processing is a near-net-shape or net-shape processing technology. Through one-time molding with molds, it greatly reduces material waste and processing time. Compared with traditional cutting processing, the production efficiency can be increased by 3 - 5 times, effectively reducing production costs and meeting customers' needs for large-volume and short-delivery orders.

- Excellent Quality:We adopt advanced mold manufacturing technology and strict production process control. From raw material inspection, mold debugging to real-time monitoring during the production process, we ensure stable and reliable product quality. The produced cold headed parts have good metal flow lines, excellent mechanical properties, and high surface finish, and can meet the requirements of various harsh usage environments.

- Customized Services:We have a professional design and R & D team, which can provide personalized product design and mold development services according to customers' special needs. Whether it is a complex shape structure or special performance indicators, we can rely on our rich experience and innovative technology to create unique cold headed products for customers.

IV. Applicable Scenarios

- Automotive Manufacturing Industry:Used for producing automotive engine components, chassis fasteners, body connectors, etc., such as bolts, nuts, pins, and other standard parts, as well as special-shaped high-strength structural parts, providing guarantees for the safety and reliability of automobiles.

- Electronics and Electrical Appliances Industry:Suitable for manufacturing various precision components of electronic devices, such as electronic connectors, plug-ins, terminals, etc., meeting the development trend of miniaturization and precision of electronic products.

- Construction Hardware Field:It can produce various hardware parts required in construction and decoration, such as screws, rivets, expansion bolts, etc. The products are high in strength and corrosion-resistant, and are widely used in building structure connections and decoration.

• 4. Machinery Manufacturing Industry:It produces various transmission parts, connectors, and fasteners for mechanical equipment, such as shaft parts, gear blanks, nuts, etc., ensuring the normal operation and stable performance of mechanical equipment.

Amy Ho

Amy Ho