Customized Non-Standard Parts

Swiss-Type Machining Service Introduction

Service Introduction

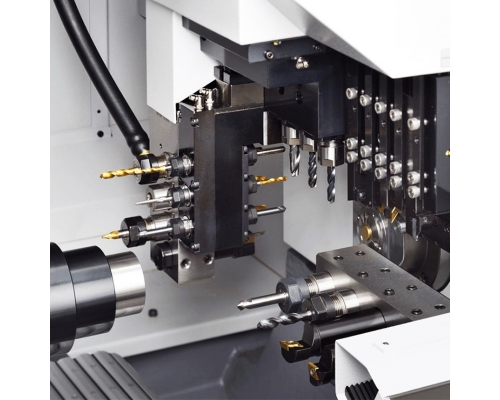

Swiss-Type Machining is a high-precision and high-efficiency CNC compound machining technology. Through the coordinated movement of the spindle box and tools, it can complete multiple complex processes such as turning, milling, drilling, and tapping in a single clamping. It is especially suitable for the precision machining of slender shaft-type and complex-shaped parts. Relying on advanced imported equipment and mature processes, we provide customers with one-stop solutions ranging from single-piece customization to mass production, ensuring that the machining accuracy of parts reaches the micron level and meets the requirements of high-precision manufacturing.

Machining Capabilities

- Materials:A wide range of metallic and non-metallic materials, including stainless steel, aluminum alloy, titanium alloy, copper alloy, engineering plastics, etc.

- Precision:Dimensional accuracy up to ±0.001mm, roundness ≤0.0005mm, surface roughness Ra≤0.8μm.

- Machining Range:Capable of processing shaft parts with a diameter of 0.5 - 32mm and a length of 1 - 200mm. It can handle complex machining requirements such as internal and external diameter contours, eccentric holes, and multi-plane milling.

- Equipment Advantages:Equipped with more than 20 imported Swiss-type CNC lathes (such as Citizen and Tsugami from Japan), supporting 24-hour automated production with a monthly capacity of over 100,000 pieces.

Core Advantages

- High Precision and Stability:Precise control of spindle synchronous feeding and tool paths reduces vibration and errors, ensuring high-precision machining of complex parts.

- High Efficiency and Low Cost:Completing multiple processes in one clamping reduces clamping times and equipment occupancy, increasing production efficiency by over 50% and reducing overall costs by 30%.

- Flexible Customization:Supports low-volume prototyping (minimum order quantity of 50 pieces) and large-scale mass production, quickly responding to diverse customer needs.

- Full-process Service:Provides one-stop services covering process design, mold development, production, and quality inspection, with professional engineering teams offering technical support.

Application Scenarios

Widely applied in high-end manufacturing sectors such as electronics and telecommunications, medical equipment, aerospace, automotive components, and precision instruments, including:

- Electronics and Telecommunications:Precision connectors, plugs, rotating shafts, micro shaft parts.

- Medical Equipment:Medical bone screws, joint prostheses, surgical instrument components.

- Aerospace:Titanium alloy fasteners, high-temperature alloy parts, precision transmission components.

- Automotive Components:Sensor housings, electric vehicle motor shafts, precision gear shafts.

Amy Ho

Amy Ho